ETFE permanent transparent film material

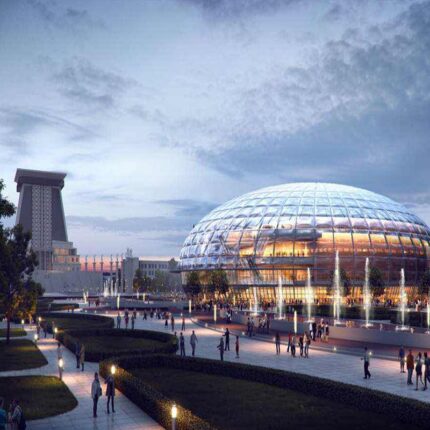

“ETFE ( Ethylene Tetrafluoroethylene Copolymer) the thickness of ETFE membrane . The thickness of ETFE membrane used in construction is usually about 0.25mm, which is a transparent membrane material. This membrane material was used in venues such as the National Stadium and the National Aquatics Center for the 2008 Beijing Olympics.

ETFE membrane materials are often used as air pillows in membrane structures. The earliest ETFE project has a history of more than 20 years, and the most famous one is the Garden of Eden in England.

ETFE film is a superior alternative material in transparent building structures, and has been proven to be a reliable and economically practical roofing material in many projects over the years due to its numerous advantages. This film is made of artificial high-strength fluoropolymer (ETFE), and its unique anti adhesive surface gives it high anti fouling and easy to clean characteristics. Usually, rainwater can remove the main dirt.

ETFE membrane has a service life of at least 25-35 years and is an ideal material for permanent multi-layer movable roof structures. This membrane material is commonly used for two-story or three-layer inflatable support structures with a span of 4 meters (currently up to 8 meters or more), and the membrane span can also be increased according to the geometric and climatic conditions of special projects. The length of the membrane is generally 15-30 meters based on ease of installation. Small span single-layer structures can also be used with smaller specifications.

ETFE film meets the B1 and DIN4102 fire rating standards and will not drip during combustion. And the membrane is very lightweight, only 0.15-0.35 kilograms per square meter. This characteristic gives it considerable advantages even in cases of film melting caused by smoke or fire.

According to the location and surface printing, the transmittance of ETFE film can reach up to 95%, and currently, the transmittance of high transparency defogging products can reach over 98%. This material does not block the transmission of ultraviolet and other light to ensure natural light inside the building. By surface printing, the translucency of the material can be further reduced to 50%. According to geometric conditions and the number of layers in the membrane, its K value can reach up to 2.0W/m2K. Taking a three-layer printed film as an example, the energy consumption index can reach 0.77.

Due to its excellent quality, ETFE film requires almost no daily maintenance. A simple inspection (once a year is recommended) can be conducted on the roof due to mechanical damage, and on-site repairs can be carried out as needed. At the same time, the ventilation system can also be checked and the filtering device can be replaced.

ETFE membranes are completely recyclable materials that can be reused to produce new membrane materials or to separate impurities and produce other ETFE products.”